-

Henkel 31361 LOCTITE® LB 8209 Krytox® White RFE PFPE High Performance Lubricant - 454 Gram (16 oz) Cartridge

Henkel 31361 LOCTITE® LB 8209 Krytox® White RFE PFPE High Performance Lubricant - 454 Gram (16 oz) Cartridge

PART #: SGP32957MFR PART #: 237158Our Price: $347.22 (Each)QTY: Add to Cart -

DUPONT™ MOLYKOTE® 55 White O-Ring Grease - 3.6 Kg (8 lb) Pail

DUPONT™ MOLYKOTE® 55 White O-Ring Grease - 3.6 Kg (8 lb) Pail

PART #: SGP39244MFR PART #: 4016068Our Price: $673.51 (Each)QTY: Add to Cart -

DUPONT™ MOLYKOTE® 111 Translucent White Valve Silicone Lubricant & Sealant - 150 Gram (5.3 oz) Tube

DUPONT™ MOLYKOTE® 111 Translucent White Valve Silicone Lubricant & Sealant - 150 Gram (5.3 oz) Tube

PART #: SGP40787MFR PART #: 4109788Our Price: $24.48 (Each)QTY: Add to Cart -

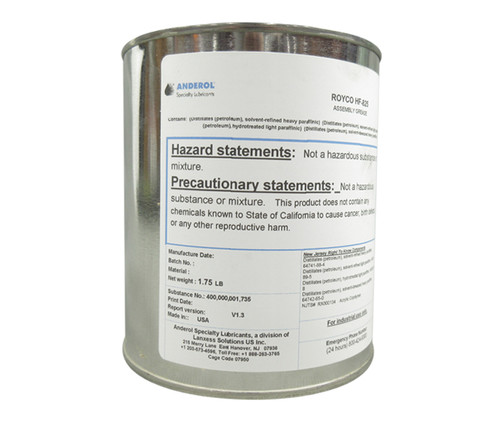

ROYCO® HF-825 Yellow Acryloid Assembly Fluid & O-Ring Lubricant - 1.75 lb Can

ROYCO® HF-825 Yellow Acryloid Assembly Fluid & O-Ring Lubricant - 1.75 lb Can

PART #: SGP76270MFR PART #: 58323745Our Price: $116.06 (Each)QTY: Add to Cart -

Parker-Hannifin OLUBE 884-2 O-Lube O-Ring Lubricant - 2 oz Tube

Parker-Hannifin OLUBE 884-2 O-Lube O-Ring Lubricant - 2 oz Tube

PART #: SGP79816MFR PART #: OLUBE-884-2Our Price: $13.69 (Each)QTY: Add to Cart -

Henkel 29710 LOCTITE® LB 8209™ Krytox® White RFE PFPE High Performance Lubricant - 56 Gram (2 oz) Tube

Henkel 29710 LOCTITE® LB 8209™ Krytox® White RFE PFPE High Performance Lubricant - 56 Gram (2 oz) Tube

PART #: SGP28493MFR PART #: 234339Our Price: $73.58 (Each)QTY: Add to Cart -

DUPONT™ MOLYKOTE® 111 Translucent White Valve Silicone Lubricant & Sealant - 400 Gram (14 oz) Cartridge

DUPONT™ MOLYKOTE® 111 Translucent White Valve Silicone Lubricant & Sealant - 400 Gram (14 oz) Cartridge

PART #: SGP40788MFR PART #: 4109803Our Price: $62.01 (Each)QTY: Add to Cart -

Parker-Hannifin SLUBE-884-2 Super O-Lube O-Ring Lubricant - 2 oz Tube

Parker-Hannifin SLUBE-884-2 Super O-Lube O-Ring Lubricant - 2 oz Tube

PART #: SGP79815MFR PART #: SLUBE-884-2Our Price: $32.00 (Each)QTY: Add to Cart

We've all had epic battles with O-rings. If you're like us, you don't win every fight. With the right O-ring lubricant in your corner, though, you can improve your odds. We've put together a collection designed to ensure a snug fit without compromising the integrity of the seal it creates.

Our selection includes O-ring lubricants from heavy hitters in the aviation industry: Dow Corning, Parker and ROYCO—all ready to serve you the slick.

Our O-ring lubes manage to pack a powerful punch as they facilitate installation and prolong the life of these gaskets. How? By sparring with corrosive elements and oxidation. In addition, these lubes are able to go 15 rounds or more with wide temperature ranges and are compatible with several types of plastics and elastomers. They also act as preventative measures; O-rings when well lubed are not prone to chafing or tearing. Ding-ding-ding! You are sure to be a winner with these products.