SkyGeek’s Guide to the Industrial Uses of Phosphate Ester Fluids

Aug 24th 2023

Understanding Phosphate Ester Fluids: Key Characteristics and Industrial Uses

A SkyGeek Guide to Industrial Phosphate Ester Uses

Hydraulic fluids are essential for operating and controlling systems in a variety of industries, including aviation, though they are also used in industrial machinery, transportation and power generation. These highly capable fluids help transmit power, reduce wear and ensure smooth, reliable performance under high pressures and temperatures.

One specialized type of hydraulic fluid is phosphate ester hydraulic fluid, which is known for its exceptional fire resistance and reliable performance in extreme temperatures. Phosphate ester fluids are made of synthetic compounds, which gives them the stability needed for high-temperature, high-stress applications. Because of this, phosphate ester fluids are a preferred choice in environments where fire safety is critical, such as aircraft systems and industrial power equipment.

At SkyGeek, we carry top-quality phosphate ester fluids like Eastman’s industrial-grade formulas to meet your needs. While effective, these fluids can pose environmental risks if mishandled, so proper storage and use are crucial. In this free guide, you'll find expert insights and a helpful FAQ to answer common questions and ensure safe use.

What are Phosphate Ester Fluids?

Phosphate ester fluids are a type of synthetic hydraulic fluid derived from the esterification of phosphoric acid with alcohols. This chemical reaction forms esters — organic compounds where the hydrogen in phosphoric acid is replaced with either alkyl or aryl groups. The fluids are known for their high thermal stability, low volatility and inherent fire resistance, which makes them valuable in high-temperature environments.

There are two main types of phosphate ester fluids based on their molecular structure:

Triaryl phosphate esters are composed of three aromatic (aryl) groups bonded to a phosphate group. These fluids offer superior thermal stability and chemical resistance, making them ideal for demanding applications like for use as aerospace hydraulic fluid.

- Alkyl phosphate esters, in contrast, contain one or more aliphatic (alkyl) groups. While typically more biodegradable and less toxic, they tend to have lower thermal stability compared to triaryl esters.

Unlike mineral-based hydraulic fluids, which are derived from petroleum, phosphate ester fluids are fully synthetic, offering more consistent performance across a wide temperature range. The synthetic nature of the industrial hydraulic fluid allows for improved oxidation resistance and protection against wear while still being compatible with most seals and elastomers. This is one of the primary phosphate ester characteristics.

Hydraulic Fluid Properties

Phosphate ester fluids exhibit a number of desirable properties that make them ideal for use in high-risk and high-demand hydraulic systems including:

- High fire resistance: Thanks to their unique chemical structure, phosphate ester fluids have a high flash point and low volatility, making them difficult to ignite. Referred to as fire-resistant hydraulic fluid.

- Excellent thermal stability: These fluids maintain performance even at elevated temperatures, ensuring long-term reliability in systems exposed to intense heat.

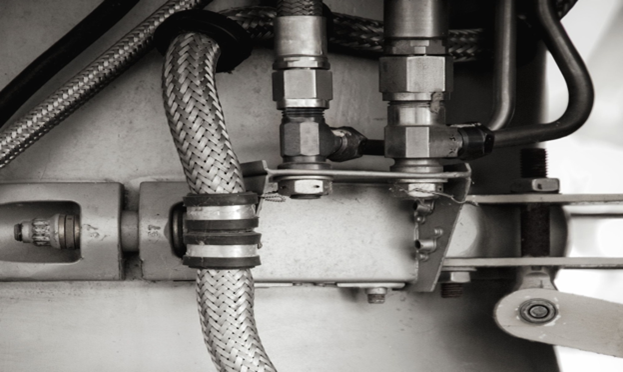

- Good lubrication properties: Phosphate esters offer excellent lubricating capabilities, helping to reduce wear and extend the lifespan of pumps, valves and other hydraulic components, even under heavy loads and high pressures.

- Corrosion resistance: Their formulation helps prevent rust and corrosion on internal metal surfaces, protecting system integrity over time.

- High-pressure performance: Phosphate ester fluids can withstand high pressures without losing effectiveness.

- Material compatibility: While phosphate esters are compatible with fluorocarbon and certain thermoplastic materials, they may degrade natural rubber and some elastomers.

- Hydrolytic stability (potential drawback): In the presence of water, phosphate esters can undergo hydrolysis, leading to fluid breakdown and acid formation. This can be mitigated with regular maintenance, water contamination monitoring and the use of system dryers or water-absorbing filters.

Industrial Applications and Uses

Phosphate ester fluids are widely used across various industries due to their exceptional fire resistance, thermal stability and high-pressure performance. In the aerospace industry, they play a critical role in aircraft hydraulic systems, powering landing gear, brakes and flight control surfaces.

In the power generation sector, phosphate ester fluids are commonly used in steam turbines and turbine control systems. These high-temperature, high-pressure applications demand a fluid that can reduce fire risk while maintaining system reliability. Similarly, in industrial hydraulics, phosphate esters are used in machinery operating under hazardous conditions. Their inherent fire resistance adds an extra layer of safety when ignition sources are present.

Beyond these primary industries, phosphate ester fluids are also found in specialized applications like hydraulic presses and extruders, where both thermal performance and fire protection are critical to maintaining safety and efficiency.

Advantages of Using Phosphate Ester Fluids

Phosphate ester fluids offer a combination of fire resistance, thermal stability and reliable lubrication that make them ideal for high-risk industrial environments. Their ability to withstand extreme temperatures and pressures helps enhance performance reliability while their fire-resistant chemistry significantly reduces risks. These properties translate into safer operations and longer system life, particularly in industries where safety and performance are non-negotiable.

Drawbacks and Considerations

Despite their advantages, phosphate ester fluids also have some drawbacks, including higher costs, hydrolytic instability and material compatibility issues with certain seal materials. These factors require careful system design, regular maintenance, and proper handling to ensure safe and efficient operation.

Conclusion

Phosphate ester fluids play a vital role in the aviation industry, especially in mission-critical applications where fire resistance, thermal stability and excellent lubrication are non-negotiable. Their unique characteristics such as high flash points, chemical stability, and compatibility with demanding environments, make them the ideal choice for the toughest environments. To ensure optimal performance and safety, it’s important to choose the phosphate ester fluid that is tailored to your specific needs. We encourage you to explore the range of specialized phosphate ester products available at SkyGeek, or reach out to our experts for personalized guidance and suggestions.

Phosphate Ester Fluids - FAQ

What is the primary use of phosphate ester fluids?

Phosphate ester fluids are primarily used as fire-resistant hydraulic fluids in applications involving high temperatures and pressures, such as aviation, power generation and mining.

What are the main types of phosphate ester fluids?

The two main types of phosphate ester fluids are (1.) triaryl phosphate esters, made from three aryls (aromatic) groups bonded to a phosphate group; and, (2.) alkyl phosphate esters, which consist of one or more alkyl (aliphatic) groups bonded to a phosphate group.

Are phosphate ester fluids biodegradable?

The biodegradability of phosphate ester fluids depends on their chemical structure. Alkyl phosphate esters are generally more biodegradable and less toxic than triaryl phosphate esters.

How do phosphate ester fluids compare to conventional hydraulic fluids in terms of cost?

Phosphate ester fluids are more expensive than conventional hydraulic fluids due to their specialized nature and unique properties, such as fire resistance and high-temperature performance.

What safety precautions should be taken when handling phosphate ester fluids?

When handling phosphate ester fluids, appropriate safety precautions include using personal protective equipment (PPE) such as gloves and protective eyewear, ensuring adequate ventilation, proper storage in sealed containers away from heat sources and open flames and implementing spill containment and clean-up measures.