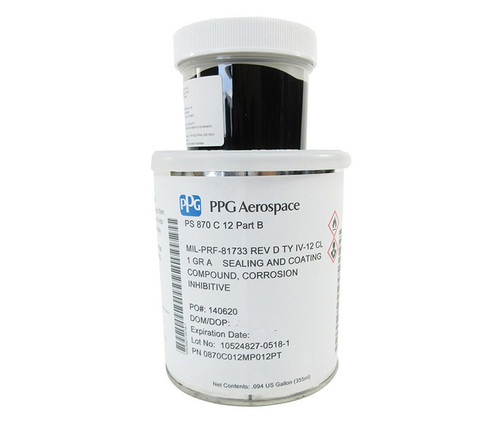

When corrosion starts lurking in the shadows, choose PPG® P/S 870 C-12 Corrosion Inhibitive Sealant from SkyGeek to act as a physical barrier against corrosion-causing liquids. PPG® P/S 870 C-12 Corrosion Inhibitive Sealant steps up like a champ and delivers the protection needed to keep your aircraft in top condition. Designed to meet MIL-PRF-81733D Type IV-12, Class 1, GA specifications, this sealant doesn’t just play by the rules — it wrote them. Tailored for long cure applications, it’s perfect for sealing where strength, longevity and military-grade performance are a must.

If you're tired of sealants that start curing before they’re in place, the 12-hour work life of PPG® P/S 870 C-12 Corrosion Inhibitive Sealant is sure to please. With the extended work time, you’ve got all the time in the world — or at least a full shift — to get your application just right. That means you can smush, mush, push and press the sealant until your heart’s content, getting the placement just right. It’s ideal for scenarios where meticulous attention to detail matters, such as fuel tank assemblies, access panels or anywhere corrosion likes to stake a claim.

Once cured, this sealant forms a resilient, flexible barrier that stands strong against fuel, water and hydraulic fluids — the three most common causes of corrosion on an airplane. Its corrosion-fighting properties have been tested over and over again, and it doesn’t back down when things get tough. The sealant is sold in a pint-size kit so you’ll always have plenty of product for your toughest jobs. The two-part formula is easy to mix and the pre-measured components take the guesswork out of achieving the perfect ratio.

| Application Properties (typical) | | | Color | Part A - Black

Part B - White

Mixed - Gray | | Mixing ratio by weight | Part A: Part B

17:100 | | Base Viscosity | 2,500, (250)

(Brookfield #6 @ 10rpm), Poise (Pa-s) | Application life and cure time

@ 77°F (25°C), 50% RH | | | Application life (hours) | Tack free time (hours) | Cure time to 30 A Durometer (days) | | C-12 | 12 | 20 | 14 | | C-24 | 24 | 80 | 21 | | C-48 | 48 | 168 | 56 | | |

| Performance Properties (typical) | | | Cure Time | Cured in accordance with MIL-S-81733 Type IV | | Cured specific gravity | 1.50 | | Nonvolatile content,(%) | 90% | | Ultimate cure hardness (Durometer A) | 50 | | Peel strength, pli (N/25 mm),100% cohesion | | JP-4 fluid immersion, 2 days @ 140°F (60°C) | 3% fuel/NaCl-H2O immersion, 2 days @ 140°F (60°C) | | MIL-A-8625 (Anodized aluminum) - 21 (93) | MIL-A-8625 (Anodized aluminum) - 25 (111) | | MIL-T-9046 (Titanium comp. C)* - 26 (116) | MIL-T-9046 (Titanium comp. C)* - 26 (116) | | *Primed with PR-148 Adhesion Promoter | | | Tensile strength, psi (KPa) | 250 (1724) - Standard cure,14 days @77°F(25°C), 50% RH | | Elongation, % | 250 - Standard cure,14 days @77°F(25°C), 50% RH | | Soluble chromate, % | 4 | | Low temperature flexibility @ -65°F (-54°C) | No cracking, checking or loss of adhesion. | | Resistance to hydrocarbons | Weight loss : 7.0% - 7 days @ 140°F(60°C) immersed in Type III fuel. | | Flexibility | No cracks after bending 180 degrees over 0.125 inch (3.18 mm) mandrel. | | Repairability to itself | Excellent to both freshly cured as well as fuel aged and abraded fillets. | | Salt spray (fog) test for 1000 hrs. (ASTM B117) | No corrosion to base substrate or deterioration of sealant. | | Fungus resistance | Non-nutrient | |

Note: The application and performance property values above are typical for the material, but not intended for use in specifications or for acceptance inspection criteria because of variations in testing methods, conditions and configurations.

Surface preparationImmediately before applying sealant to primed substrates, the surfaces should be cleaned with solvents. Contaminants such as dirt, grease, and/or processing lubricants must be removed prior to sealant application.

A progressive cleaning procedure should be employed using the appropriate solvents and new lint free cloth (reclaimed solvents or tissue paper should not be used). Always pour solvent on the cloth to avoid contaminating the solvent supply. Wash one small area at a time.

It is important that the surface is dried with a second clean cloth prior to the solvent evaporating to prevent the redeposition of contaminants on the substrate.

Substrate composition can vary greatly. This can affect sealant adhesion. It is recommended that adhesion characteristics to a specific substrate be determined prior to application on production parts or assemblies.

For a more thorough discussion of proper surface preparation, please consult the SAE Aerospace Information Report AIR 4069. This document is available through SAE, 400 Commonwealth Avenue, Warrendale, PA 15096-0001.

Mixing instructions

P/S 870 Class C is supplied in a two-part kit. Mix according to the ratios indicated in the application properties section. Mix Part A and Part B separately to uniformity, then thoroughly mix entire contents of both parts of the kit together taking care to avoid leaving unmixed areas around the sides or bottom of the mixing container.

Storage life

The storage life of P/S 870 Class C is at least 6 months when stored at temperatures below 80°F (27°C) in original unopened containers.

Health precautions

This product is safe to use and apply when recommended precautions are followed. Before using this product, read and understand the Material Safety Data Sheet (MSDS), which provides information on health, physical and environmental hazards, handling precautions and first aid recommendations. An MSDS is available on request. Avoid overexposure. Obtain medical care in case of extreme overexposure.

For industrial use only. Keep away from children.

For emergency medical information call 1-800-228-5635.

Safety Data Sheet

Safety Data Sheet

INTERNATIONAL SHIPPING

INTERNATIONAL SHIPPING

HAZMAT ORDERS

HAZMAT ORDERS

Country of Origin

Country of Origin