Approvals and Conformities

Product Attributes

Country of Origin

Country of Origin

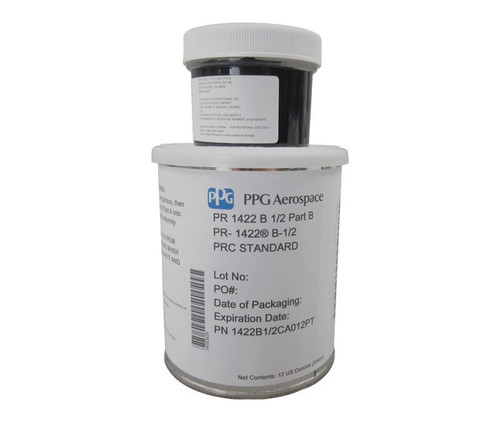

When your fuel tank demands a seal that won’t budge, leak or flake out under pressure, trust PPG® PR-1422 B-1/2 Brown PRC Standard Spec Fuel Tank Sealant from SkyGeek to get the job done right. This brown fuel tank sealant is sold in a pint-size kit, but don’t let the size fool you. Despite the relatively small container, this sealant packs a serious punch and is strong enough to keep your fuel system in check. Made for professionals who don’t gamble with leaks and need a sealant that actually shows up to work, PPG® PR-1422 B-1/2 Brown PRC Standard Spec Fuel Tank Sealant from SkyGeek is perfect for aviation, aerospace and anyone who needs to secure joints with a long-lasting, flexible bond.

This PR1422B1/2 kit features a 30-minute work life, which translates to just enough time to get the job done without racing the clock. Once cured, it forms a firm, but resilient seal that holds up against fuel, oil, and environmental exposure, making it a go-to B 1/2 sealant in both OEM and maintenance settings. The sealant is designed to be easy to apply, getting into nooks and crannies with ease before curing begins. Once cured, it maintains its elastomeric properties, so turbulence, vibration and fluctuating temperatures are never a problem.

Whether you know it as PR 1422, pr1422, or just “the good stuff,” this PR 1422 sealant has earned its reputation for consistent performance and professional-grade results. Use it to repair, reseal, or build from scratch. It’s easy to apply, reliable under pressure and a must-have for any serious tech's toolbox. The two-part slant is sold in a pint-size kit with pre-measured components for convenience.

If you need a B1/2 sealant that can handle jet fuel without flinching, this is the one. Crack open the pint, spread some confidence, and seal with authority.

Features

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||

Note: The application and performance property values above are typical for the material, but not intended for use in specifications or for acceptance inspection criteria because of variations in testing methods, conditions and configurations.

Surface preparationImmediately before applying sealant to primed substrates, the surfaces should be cleaned with solvents. Contaminants such as dirt, grease, and/or processing lubricants must be removed prior to sealant application.

A progressive cleaning procedure should be employed using the appropriate solvents and new lint free cloth (reclaimed solvents or tissue paper should not be used). Always pour solvent on the cloth to avoid contaminating the solvent supply. Wash one small area at a time.

It is important that the surface is dried with a second clean cloth prior to the solvent evaporating to prevent the redeposition of contaminants on the substrate. Substrate composition can vary greatly. This can affect sealant adhesion. It is recommended that adhesion characteristics to a specific substrate be determined prior to application on production parts or assemblies.

For a more thorough discussion of proper surface preparation, please consult the SAE Aerospace Information Report AIR 4069. This document is available through SAE, 400 Commonwealth Avenue, Warrendale, PA 15096-0001.

Mixing instructions

PR-1422 Class B is supplied in a two-part kit. Mix according to the ratios indicated in the application properties section. Mix Part A and Part B separately to uniformity, then thoroughly mix entire contents of both parts of the kit to-gether taking care to avoid leaving unmixed areas around the sides or bottom of the mixing container.

Storage life

The storage life of PR-1422 Class B is at least 9 months when stored at temperatures between 40°F (5°C) and 80°F (27°C) in original unopened containers.

Health precautions

This product is safe to use and apply when recommended precautions are followed. Before using this product, read and understand the Material Safety Data Sheet (MSDS), which provides information on health, physical and environmental hazards, handling precautions and first aid recommendations. An MSDS is available on request. Avoid overexposure. Obtain medical care in case of extreme overexposure.

For industrial use only. Keep away from children.

For emergency medical information call 1-800-228-5635.

INTERNATIONAL SHIPPING

INTERNATIONAL SHIPPING