Country of Origin

United States

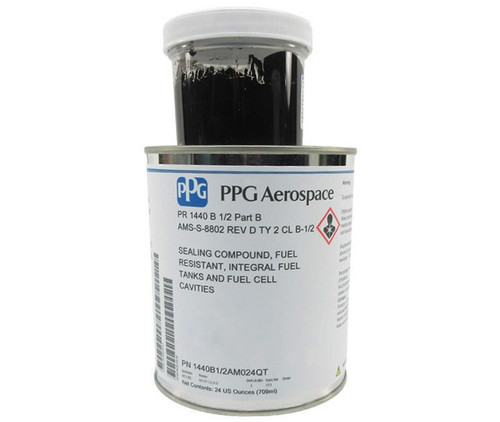

Manufacturer P/N

PR-1440 B-1/2

Schedule B Code

3214.10.0010

Ship Dimensions

4 x 4 x 7 inches

Spec

AMS-S-8802D Type 2, Class B-1/2

PPG® PR-1440 B-1/2 Fuel Tank Sealant – Quart Kit offers a reliable, fast-curing solution for aviation fuel system sealing. This two-part manganese dioxide-cured polysulfide sealant provides a strong, flexible bond with excellent elastomeric properties, ensuring leak protection and durability across temperatures from -65°F to 250°F. Its low-sag gray formula applies smoothly by extrusion gun or spatula, ideal for fillet sealing and other applications. Pre-measured components simplify mixing for consistent results every time, making it a trusted choice to maintain your aircraft’s fuel tank integrity.

| Application Properties (typical) | | | Color | Part A - Black

Part B - Off White

Mixed - Dark Gray | | Mixing ratio by weight | Part A: Part B

10:100 | | Base Viscosity | 10,000, (1000)

(Brookfield #6 @ 10rpm), Poise (Pa-s) | Application life and cure time

@ 77°F (25°C), 50% RH | | | Application life (hours) | Tack free time (hours) | Cure time to 35 A Durometer (hours) | | B-1/2 | 1/2 | <10 | 30 | | B-2 | 2 | <36 | 48 | | |

| Performance Properties (typical) | | | Cure Time | 14 days @ 77°F (25°C), 50% RH | | Cured specific gravity | 1.57 | | Nonvolatile content,(%) | 97% | | Ultimate cure hardness (Durometer A) | 50 | | Peel strength, pli (N/25 mm),100% cohesion | | JRF immersion, 7 days @ 140°F (60°C) | JRF/NaCl-H2O immersion, 7 days @ 140°F (60°C) | | MIL-A-8625 (Anodized aluminum) - 28 (125) | MIL-A-8625 (Anodized aluminum) - 35 (156) | | MIL-C-5541 (Alodine aluminum) - 30 (133) | MIL-C-5541 (Alodine aluminum) - 35 (156) | | MIL-C-27725 (IFT coating) - 30 (133) | MIL-C-27725 (IFT coating) - 34 (151) | | MIL-S-5059 (Stainless steel)* - 31 (138) | MIL-S-5059 (Stainless steel)* - 35 (156) | | MIL-T-9046 (Titanium comp. C)* - 36 (160) | MIL-T-9046 (Titanium comp. C)* - 30 (133) | | QQ-A-250/13 (Alclad) - 25 (111) | QQ-A-250/13 (Alclad) - 32 (142) | | *Primed with PR-148 Adhesion Promoter | | | Tensile strength, psi (KPa) | 300 (2070) - Standard cure,14 days @77°F(25°C), 50% RH | | Elongation, % | 363 - Standard cure,14 days @77°F(25°C), 50% RH | | Thermal rupture resistance | Retains pressure of 10 psi with only negligible deformation, both before and after immersion in JRF. | | Low temperature flexibility @ -65°F (-54°C) | No cracking, checking or loss of adhesion. | | Corrosion resistance | No corrosion, adhesion loss, softening, or blistering after 20-day immersion in 2-layer salt water/JRF @ 140°F (60°C). | | Resistance to hydrocarbons, Weight loss, % | 4.5% - 7 days @ 140°F(60°C) immersed in JRF. | | Flexibility | No cracks after bending 180 degrees over 0.125 inch (3.18 mm) mandrel. | | Repairability to itself | Excellent to both freshly cured as well as fuel aged and abraded fillets. | | Resistance to other fluids | Excellent resistance to water, alcohols, petroleum-base and synthetic lubricating oils, and petroleum-base hydraulic fluids. | | Fungus resistance | Non-nutrient | |

Note: The application and performance property values above are typical for the material, but not intended for use in specifications or for acceptance inspection criteria because of variations in testing methods, conditions and configurations.

Safety Data Sheet

Safety Data Sheet

Country of Origin

Country of Origin

INTERNATIONAL SHIPPING

INTERNATIONAL SHIPPING