Approvals and Conformities

Product Attributes

Country of Origin

Country of Origin

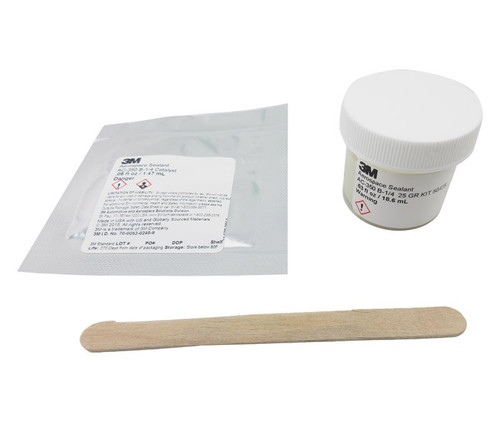

The 3M™ AC-350 B-1/4 Fuel Tank Sealant from SkyGeek is a premium-quality sealant specifically formulated for use in the fuel tank of your aircraft. The aerospace sealant is designed to meet the demanding needs of aviation and aerospace applications, forming a strong, leak-free bond to keep critical systems safe and operational. This product is formulated to provide exceptional sealing performance, ensuring robust protection against environmental factors such as moisture, chemicals and extreme temperatures. The sealant is resistant to aviation gasoline and jet fuels. 3M™ AC-350 B-1/4 Fuel Tank Sealant comes in a convenient 25-gram package, making it ideal for precision application in both small-scale repairs and larger maintenance projects.

Engineered by 3M™, a leader in industrial adhesives and sealants, the 3M™ AC-350 B-1/4 Fuel Tank Sealant offers excellent adhesion properties, allowing it to bond effectively with various substrates commonly used in the aerospace industry, including metals and composites. Its advanced formulation ensures that it maintains flexibility over time, preventing cracking or degradation even under the stress of high-altitude conditions. This makes it an essential component for maintaining the integrity and safety of aircraft structures. Because the sealant cures quickly, maintenance and repair tasks are easily streamlined, resulting in less downtime.

The product is easy to mix and apply, thanks to its user-friendly packaging and precise catalyst-to-sealant ratio. This ensures consistent results with every use, reducing waste and improving efficiency during application. Whether used for sealing fuel tanks, pressurized cabins, or other critical components, the 3M™ AC-350 B-1/4 Fuel Tank Sealant delivers reliable performance that meets stringent industry standards. Its durability and resilience make it a trusted choice for aviation professionals seeking high-quality sealing solutions.

MMS-332 - Qualified Grade 2

AMS 3276 - B-1/4, B-1/2, B-2, B-4, B-6, B-12 Qualified

|

|

* Application life refers to the length of time the mixed compound remains at a consistency suitable for application with spatula or caulking gun. Application life is always measured as a standard temperature of 77°F with a relative humidity level of 50%. In general, for every 20°F rise in temperature, the application life is halved; and for every 20°F drop, it is doubled. High humidity levels during the mixing process will shorten application life.

** Tack-free time is the length of time after which a mixed sealant will no longer tightly adhere to L-LP-690 standard low density polyethylene film.

*** Cure time is defined as the length of time it takes AC-350 sealant to reach 30A hardness. It depends on three factors: remaining application life, temperature and relative humidity. To a certain extent, the temperature/humidity factors for application life also apply to curing. To accelerate the curing process, heat may be applied up to (but not more than) 140°F.

|

* Of cured compound after 14 days @ 77°F/50% RH

INTERNATIONAL SHIPPING

INTERNATIONAL SHIPPING