INTERNATIONAL SHIPPING

INTERNATIONAL SHIPPING

SkyGeek welcomes international orders!

Please note: International orders are shipped from their respective locations, which may take an additional 7-10 days to process. We strive to consolidate items into one shipment to minimize duties and taxes. However, if items are located in different locations, separate shipments may be necessary.

HAZMAT ORDERS

HAZMAT ORDERS

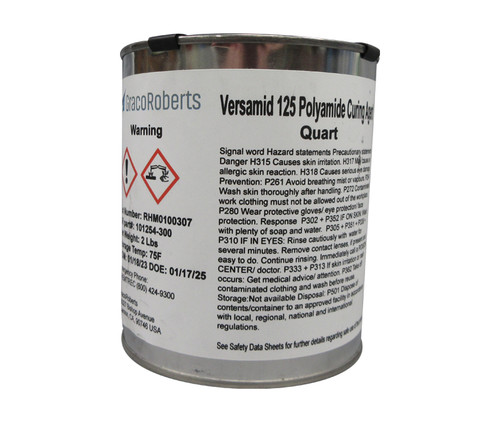

Safety Data Sheet

Warning: This product may contain a chemical known by the State of California to cause health issues. Details found here www.p65warnings.ca.gov

UN Number: UN3082

UN Class: 9

Country of Origin

Country of Origin